End Fittings & Impact Sockets

/

/

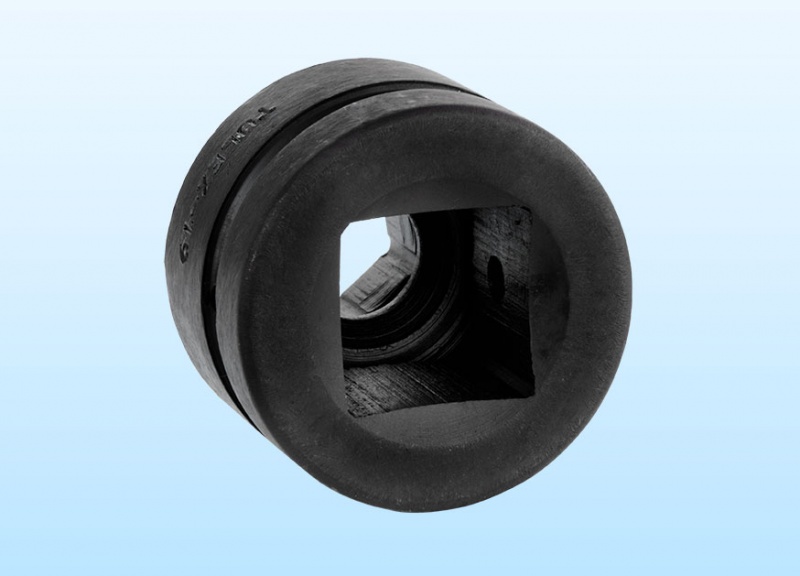

2½” Inches Heavy Duty Square Drive Impact Sockets

TULEX- Inc and metrical up to 1½” SD sizes

- From 60 mm up to 160 mm hexagon sizes

- Life time warranty for all sockets

- Made of high strength alloy steel

- Standard, deep and thinwall Sockets

- 6 point or 12 point sockets available

- Designed for heavly duty applications

- Increased protection against rusting

- Wide variety of Accessories & Adapters

- Tulex impact sockets are designed to be used with pneumatic / electric impact wrenches and nut runners. They have single hex broaching for good grip on nuts and bolts to avoid tools slipping during high speed tightening operations.

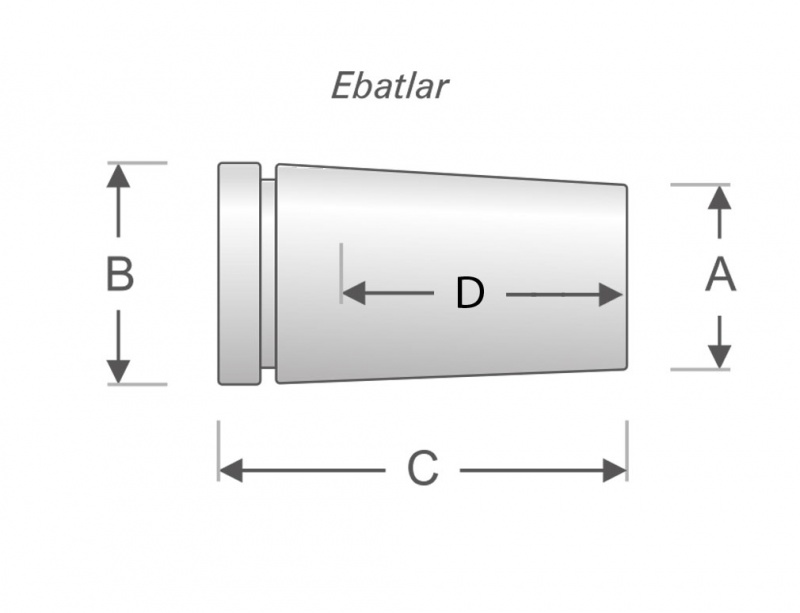

- 2½” Heavy Duty Square Drive Impact Sockets Table

| Standard Size | ||||||||

| Part Number | Square Drive | Metric Size | Hexagon Size | Socket End A |

Drive End B |

Total Length C |

Bolt Clearance Depth | Weight |

| inches | mm | mm | mm | mm | mm | mm | Kg | |

| TUM-60GI | 2½ | 39 | 60 | 105 | 122 | 140 | 82 | 7,5 |

| TUM-65 GI | 2½ | 42 | 65 | 105 | 122 | 140 | 82 | 7,5 |

| TUM-70 GI | 2½ | 45 | 70 | 117 | 122 | 145 | 87 | 8 |

| TUM-75 GI | 2½ | 48 | 75 | 117 | 122 | 145 | 87 | 8,5 |

| TUM-80 GI | 2½ | 52 | 80 | 127 | 127 | 145 | 87 | 9 |

| TUM-85 GI | 2½ | 56 | 85 | 127 | 127 | 145 | 87 | 9,5 |

| TUM-90 GI | 2½ | 60 | 90 | 140 | 127 | 160 | 102 | 11 |

| TUM-95 GI | 2½ | 64 | 95 | 140 | 127 | 160 | 102 | 12 |

| TUM-100 GI | 2½ | 68 | 100 | 155 | 127 | 160 | 102 | 14 |

| TUM-105 GI | 2½ | 72 | 105 | 155 | 127 | 160 | 102 | 14,5 |

| TUM-115 GI | 2½ | 76 | 115 | 175 | 127 | 170 | 112 | 18 |

| TUM-120 GI | 2½ | 80 | 120 | 175 | 127 | 170 | 112 | 19 |

| TUM-130 GI | 2½ | 85 | 130 | 190 | 152 | 190 | 132 | 19,5 |

| TUM-135 GI | 2½ | 85 | 135 | 190 | 152 | 190 | 132 | 22 |

| TUM-145 GI | 2½ | 90 | 145 | 210 | 152 | 195 | 137 | 25 |

| TUM-150 GI | 2½ | 90 | 150 | 210 | 152 | 195 | 137 | 30 |

| TUM-155 GI | 2½ | 90 | 155 | 220 | 152 | 200 | 142 | 35 |

| TUM-160 GI | 2½ | 100 | 160 | 220 | 152 | 200 | 142 | 40 |

- Metric/ inc sizes available

It's extra wall thickness together with special steel and heat treatment process helps absorb the shock transmitted to sockets while in use with impact wrenches. They have a conventional locking arrangement i.e. lock button or snap ring fitted on the male square drives. They can also be provided with two cross holes and groove for locking onto the impact wrench using 'O' ring and pin arrangement. These are available in 1", 1½", 2½", square drives to cover nut across flat sizes 19mm to 235 mm hexagon sizes.

It's extra wall thickness together with special steel and heat treatment process helps absorb the shock transmitted to sockets while in use with impact wrenches. They have a conventional locking arrangement i.e. lock button or snap ring fitted on the male square drives. They can also be provided with two cross holes and groove for locking onto the impact wrench using 'O' ring and pin arrangement. These are available in 1", 1½", 2½", square drives to cover nut across flat sizes 19mm to 235 mm hexagon sizes.

- High Strength Alloy Steel

All impact sockets are made from high strength alloy steel. These are heat treated for the best combination of strength and impact resistance. All impact sockets have an optimum wall thickness for strength and access on fasteners having restrictions. The depth of the hex openings is designed to accommodate the full standard fastener head. All impact socket have a ring and pin arrangement for securing them to the drive.

All impact sockets are made from high strength alloy steel. These are heat treated for the best combination of strength and impact resistance. All impact sockets have an optimum wall thickness for strength and access on fasteners having restrictions. The depth of the hex openings is designed to accommodate the full standard fastener head. All impact socket have a ring and pin arrangement for securing them to the drive.

- Extra Protection Against Rusting

The impact sockets are plated and black oxidised coated for increased protection against rusting. The Impact Socket can be manufactured with chamfered openings for ease in engagement with the drive tool and the fastener against specific requests.

-

TORQUE EQUIPMENT

TORQUE EQUIPMENT

-

Torque Screw Drivers

Torque Screw Drivers

-

Norbar Torque Wrenches

Norbar Torque Wrenches

-

Electronic Torque Wrenches

Electronic Torque Wrenches

-

Hazet Hand Torque Wrenches

Hazet Hand Torque Wrenches

-

End Fittings & Impact Sockets

End Fittings & Impact Sockets

-

Replaceable Torque Wrench Set

Replaceable Torque Wrench Set

-

Mechanical Torque Multipliers

Mechanical Torque Multipliers

-

Electric Torque Wrenches

Electric Torque Wrenches

-

Pneumatic Torque Wrenches

Pneumatic Torque Wrenches

-

Hydraulic Torque Wrenches

Hydraulic Torque Wrenches

-

Torque Wrench Pumps

Torque Wrench Pumps

-

Bolting Tools

Bolting Tools

-

Torque Tool Testers

Torque Tool Testers

-

Torque Calibration Equipment

Torque Calibration Equipment

-

Torque Transducers

Torque Transducers

-

Heavy Duty Torque Wrenches

Heavy Duty Torque Wrenches

-

Cordless Impact Wrench

Cordless Impact Wrench

-

Pneumatic Impact Wrenches

Pneumatic Impact Wrenches

-

HIGH PRESSURE HYDRAULICS

HIGH PRESSURE HYDRAULICS

-

FLANGE MANAGMENT TOOLS

FLANGE MANAGMENT TOOLS

-

HYDRAULIC HAND TOOLS

HYDRAULIC HAND TOOLS

-

WORKSHOP EQUIPMENT

WORKSHOP EQUIPMENT

-

INDUSTRIAL PRODUCTS

INDUSTRIAL PRODUCTS