Flange Spreading Equipment

/

/

SW15TE - 15 Ton Hydraulic Flange Spreader

EQUALIZER SW15TE- Capacity 15 ton

- Minimum gap 6 mm

- Spread range 81 mm

- Tool weight 14 kg

- Practical, lightweight

- Ergonomic

- With external pump

- Safe work

- Long-lasting structure

- Work faster, reduce costs

- Service and parts support in Turkey

SW15TE 15,5 Ton Hydraulic Flange Spreader

SW15TE 15,5 Ton Hydraulic Flange Spreader

Equalizer SW15TE hydraulic separator works with an external flange 700 bar hydraulic pump. It is easier to use in tight spaces via external pump flange separation equipment. Hydraulic Flange Spreader is an ideal product for hard-working areas.

It is recommended to use two separators simultaneously to more healthy and safe execution of the large flange in operation.

Contraction is prevented in one direction of the flange with the two equipments. 31 tons of push / separation force is obtained with two hydraulic flange spreader.

6 mm Flange Space is Enough for SW15TE

6 mm Flange Space is Enough for SW15TE

6 mm gap is enough to start processing. Flange connections can be opened with the use of both stepped blocks up to 83 mm. This distance is good for the necessary repair and maintenance process.

Equalizer SW15TE external pump hydraulic flange spreader can be used in natural gas plants, oil refineries, water and chemical production lines.

Allows the assembly process to be completed quickly and safely. Saves labor time. Reduces costs. Flange connection is indispensable for mounting and dismounting equipment.

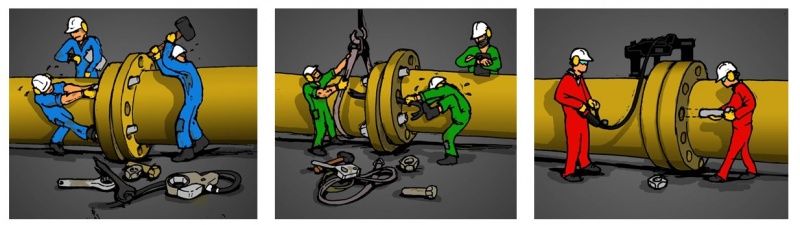

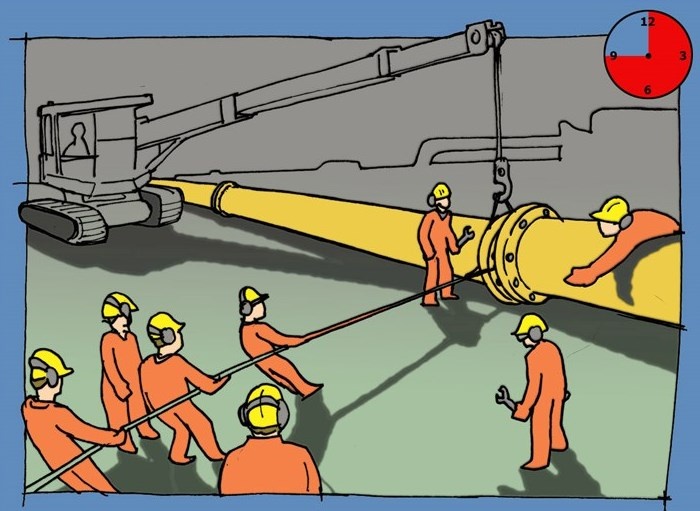

Traditional Flange Spreading and Maintenance

Traditional Flange Spreading and Maintenance

- Risk and hazards for workers

- Labor costs are higher

- Needs more workers

- Repair takes more time

- Increase the cost are to be completed late for work

Equalizer International

Flange Spreading system Advantages

- You need fewer workers.

- Labor costs are reduced

- The process is quickly finished

- Commission the system earlier

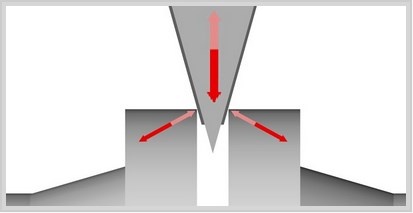

Equalizer Flange Spreader Technology

Equalizer Flange Spreader Technology

Flange equipment has been developed as a result of intensive research and development.Flange spreader has been developed in cooperation with the oil companies. (BP, Total, Shell, Esso and many more.) Flange spreading process is starting with 90° angle.Spreading-pushing force is applied directly to the flange surface and allows the opening of the flange without contraction. Sealing is never damaged. This specific feature is only provided by Equalizer Flange Spreading Technology.

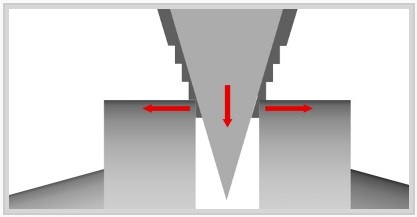

Standard Flange Spreading Method

Standard Flange Spreading Method

Standard flange spreading technology systems is in the system is slightly different. In this system, the separation force can't be applied at right angles. Spreading force will damage the flange surface thus sealing deteriorates. Deformed flanges become unusable after a while. This is why 90 degree working angle is very important for flanges.